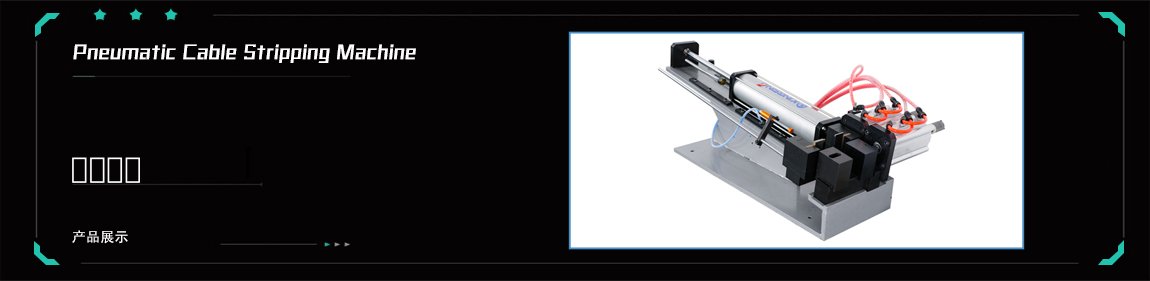

Light and portable;

Robust & reliable;

Extremely short cycle times;

Excellent price/performance ratio;

Pure pneumatic control, no need to connect the power supply, low power consumption, environmental protection and efficient.

Wire Size Range:0.03mm² – 2.08mm² (AWG32- AWG14)

Max. Outer Cable Diameter:3.2 mm (0.12")

Full strip: 0.5 mm (0.019")

Pull-off / Partial pull-off length:2 mm (0.078")

Precision of Diameter Setting:0.01 mm (0.001")

Max. Stripping Length:20 mm (0.78") (1-20mm)

Circle Time: approx. 0.3s

Net Weight:2.0 kg (4.4 lbs.)

Gross Weight:2.4 kg (5.3 lbs.)

Air Pressure:0.5-0.8Mpa

Dimensions (L × W × H):265 x 70 x 135mm

Note:

The above specifications are for reference only. In the case of extremely hard, tough wires, processing may not be possible even within the cross section range. In case of doubt, KINGSING will be happy to provide processing samples of your wires.

Conforms to the relevant CE directives on machine safety and electromagnetic compatibility.

KS-W336 has been proven thousands of times over to process wires and cables. The machine operates with extremely fast cycle times and feature a universal blade system that eliminates time consuming changeovers. Absolute precision, high cost effectiveness, and a very short return of investment are the main characteristics of this machine. The compact and slender design allows for several units to be used on one workstation and has proven most efficient particularly when processing wire harnesses and multi-core cable.

English

English